Buy the Best Coreless Motor Solutions for Your Products

The field of technology is very wide, day by day the devices are getting smaller and demanding great exactness, which is where the coreless motor has an important role to play. These special motors are different because they lack an iron core which makes them much lighter and able to respond very quickly. You can find them in small or rather precise tools like medical devices, drones, and high-end consumer electronics where space is tight and exact movement is necessary. So, with coreless motors you can get smooth power with very little noise or vibration. This is also why it is a top choice for applications which need fine control in a tiny package.

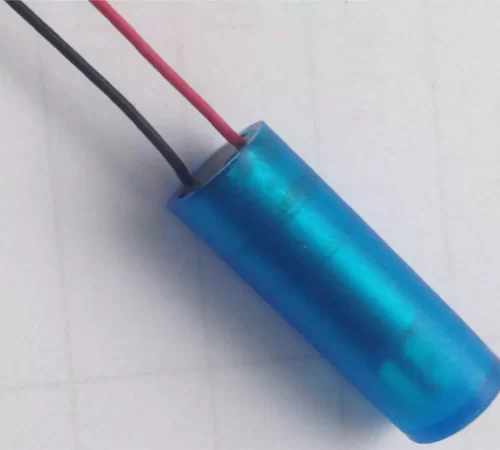

At YueQing GuangHui Electric Co., Ltd., we understand the increasing demand for motors and high speed coreless motor supplier for automation which combine small size with high accuracy. We also know that for a lot of specialized products, every millimeter and every millisecond counts. So, as a dedicated coreless DC motor supplier, we produce motors which meet these strict requirements. Our focus is on being the coreless motor provider who can offer you with miniature coreless DC motor options to power your innovations.

Features that Make Coreless Motor the Best

- Extremely Compact Size: The most striking feature of coreless motors is their very small footprint. Without a bulk iron core, they can be made much tinier than regular motors while providing better power.

- Fast Response Time: You should also know that coreless motors can start, stop, and even change direction almost instantly. Because they don’t have a heavy iron core so they can accelerate and decelerate with speed.

- Smooth Operation: The way these coreless motors are made, they have very smooth movement with minimal vibration and noise. This is because there are no cogging effects which are common for cored motors.

- High Power: Even though these motors are small in size they can turn power into motion with the best efficiency. They do not waste energy as heat or vibrations and put more of the input towards finishing the task.

- Controlled Movements: With coreless motors you can have better control over speed and position. They also have the ability to give you consistent turning force even at low speeds. This way you can get very fine and repeatable movements.

Get Precise Solutions!

You can make the better choice with coreless motors when your compact tools need accuracy, speed, and reliability. At YueQing GuangHui Electric Co., Ltd., we are your coreless motor manufacturer for high-quality precise coreless motor solutions which are made for the smallest and most demanding applications. Contact us and we will help you create tools that perform with exceptional control.

Frequently Asked Questions

What Does “Coreless” Mean in a Coreless DC Motor?

A coreless motor is a motor that has no iron core in the middle of its spinning part. In a normal motor, the copper wires are wrapped around a heavy iron block. In a coreless DC motor, the wires are wound together by themselves into a shape like a cup or a cylinder which makes the spinning part very tight.

Why is this Motor So Much Faster to Start and Stop?

This motor can start and stop very quickly because its spinning part is extremely light. Since there is no heavy iron core, the motor has very low “inertia.” This means it does not take a lot of power to get it moving, and it can stop or change direction almost instantly which is why it is sold by a high speed coreless motor supplier for automation.

How is this Motor Different From a Normal Brushed Motor?

A normal brushed motor has a heavy block of iron inside its spinning part which makes it heavy. A coreless motor does not have this iron block, so its spinning part is very light. Both types of motors still use brushes to get power, but the light weight of the coreless one means it can start and stop much faster.

Why Does this Motor Spin So Smoothly at Low Speeds?

This motor spins very smoothly because it does not have any “cogging.” Cogging is the small jerky feeling that you get in a normal motor when the magnets get “stuck” on the metal core as it turns slowly. Since a coreless DC motor has no iron core, there is nothing for the magnets to get stuck on, so it can spin without any jerking.

What Kinds of Jobs are these Coreless Motors Used for?

These coreless motors are used for any job that needs very small, quick movements. You will often find them in machines that need to start and stop almost instantly. This means things like small medical pumps, robotic hands, and high-end tattoo machines.