More Than Just Fast: The Engineering of a High-Speed Motor

Many motors can spin fast, but not many can run at 20,000 RPM or more for a long time without breaking. A true high RPM brushless motor is a piece of precision engineering. It must be built to handle the intense stress that high speeds create. This right here is how you can get a look at the hard problems that must be solved to build a motor that can handle this kind of work.

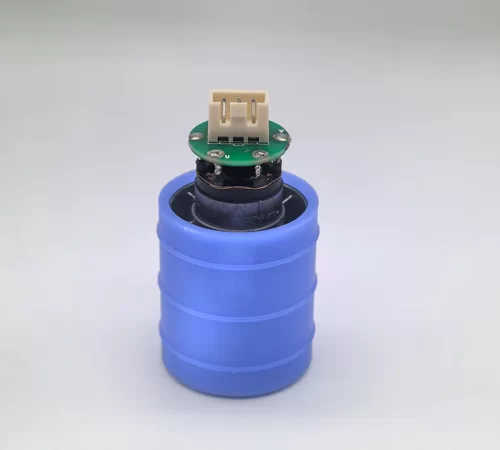

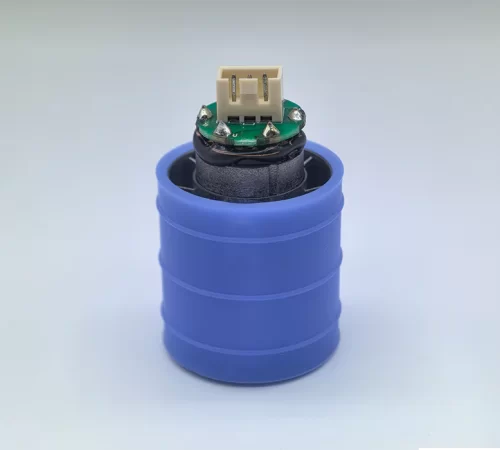

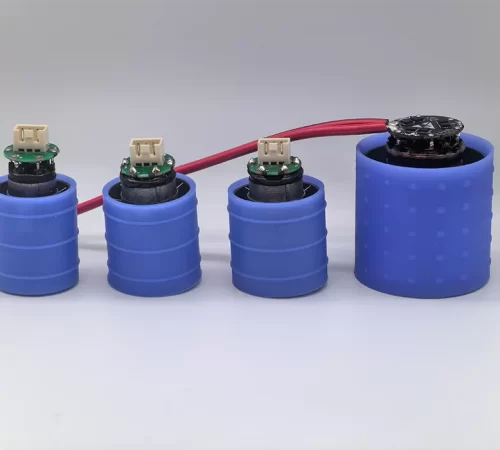

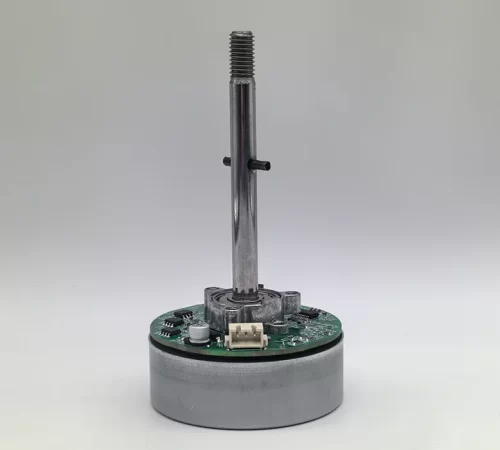

At YueQing GuangHui Electric Co., Ltd., we are a specialized high speed brushless motor manufacturer. We build our motors with better materials and very tight controls because we know that a motor for high-speed work must be perfect. As a trusted high speed brushless motor supplier, we focus on providing motors that are perfectly balanced. Our motors can handle the stress of high RPMs and will last a long time in your machine.

The Challenges of High-Speed Operation

- The Problem of Vibration: When a motor spins very fast, even a tiny spot of imbalance can cause a huge vibration. This shaking will destroy the motor’s bearings in a very short amount of time. A high-speed motor must be precision balanced to make it spin perfectly smoothly. This balancing is a key part of how it is made.

- The Problem of Heat: High speeds make a lot of heat. This heat comes from the electricity in the coils and from air friction. If this heat cannot get out of the motor then it can melt the glue on the magnets or damage the coils. A high-speed motor must be built with a design like inner-rotor layout which lets the heat escape very easily.

- The Problem of Bearing Failure: The bearings are the small balls that the motor shaft spins on. High speed puts a huge amount of stress on these small parts. A normal bearing will daily very quickly at 20,000 RPM. A real high-speed motor must be built with special high-quality bearings that can handle the speed and the heat without breaking.

- The Problem of Expansion: When the motor parts get hot, the metal begins to expand or grow by a very small amount. A high speed brushless motor manufacturer must build the motor with extremely tight tolerances. This makes sure that even when the parts get hot and expand, they do not start to rub against each other which would cause the motor to seize up.

Handle High-Speed Work!

A real high-speed motor is not just a normal motor that is rated for a faster speed. It is a special motor that has been carefully designed and built from the start. It is made to handle the heat, shaking, and stress that high RPMs will create every time. Contact us if you need a motor which can help you handle high-speed work.

Frequently Asked Questions

What Kind of RPM is a High Speed for these Motors?

High speed usually means any motor that is designed to run reliably at over 10,000 RPM. A lot of our high-speed models are built to run at speeds of 20,000 to 60,000 RPM or even higher. These are often used for medical drills or special industrial tools.

What is Precision Balancing?

Precision balancing is a process that we do at the factory. We spin each motor rotor on a special machine that finds any part of it that is even a tiny bit too heavy. We then drill a small amount of material off to make the part’s weight perfectly even all the way around which stops it from shaking.

Do These High-Speed Motors Make a Lot of Noise?

The motor itself is very quiet because it is brushless and well-balanced. The whir or whine sound that you hear from a high-speed motor is not from the motor parts rubbing. It is the sound of the motor shaft spinning and moving the air at a very high speed.

What is the Main Cause of Failure in a Motor that Spins too Fast?

The main cause of failure in a high-speed motor is almost always the bearings. If the motor is not balanced, then the bearings will shake apart. If the motor gets too hot then the grease inside the bearings will fail. This is why we use only high-quality bearings in our motors.

Do These Motors Also Need an Electronic Controller (ESC)?

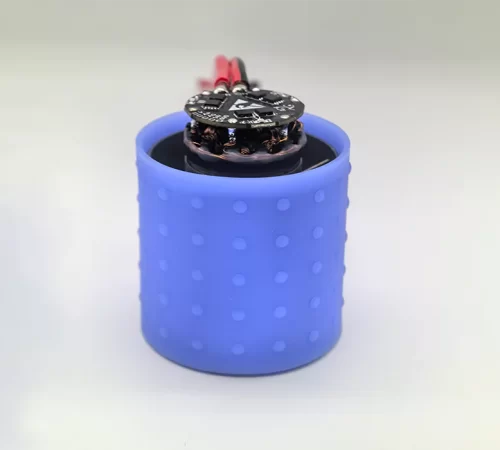

Yes, they do. These are all brushless motors, so they must have an electronic speed controller (ESC) or a driver to run. The controller is what sends the power to the motor coils in the correct order to make it spin at such high speeds.