Build Your Machine for Speed with Inner Rotor Brushless Motor

When you look at brushless motors, there are two main designs: outer rotor and inner rotor. The inner rotor brushless motor is the classic high-performance design that is used in a lot of demanding machines and tools. In this type of motor the spinning part (the rotor) is on the inside, and the stationary part (the stator) is on the outside. This makes it the best choice for jobs which need very high speed and the ability to accelerate very quickly.

At YueQing GuangHui Electric Co., Ltd., we are a specialized inner rotor motor manufacturer. We know that a motor built for high speed needs to be built with no mistakes. We build our motors with high-grade, durable bearings to make sure they can handle fast spinning for a long time. Every motor is also precision-balanced so that it spins smoothly, without a lot of vibration that can cause wear or noise in your product. As a trusted inner rotor motor supplier, we are focused on providing motors that give you high-speed performance that you can depend on and that your products need to work well in the field. We build our motors to last.

What is Different About This Motor Design?

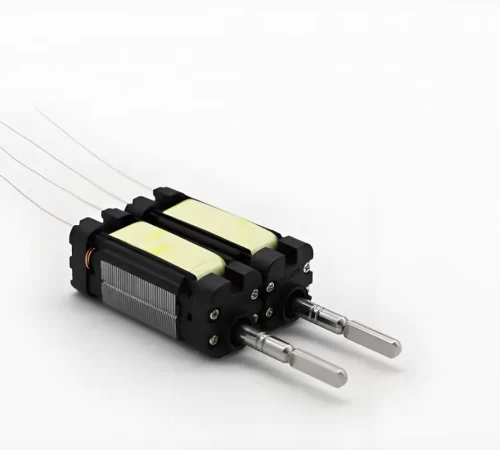

- The Design is “Standard”: This is the motor design that most people think of when they picture a brushless motor. The spinning part which is the rotor is made with strong magnets and is located in the center. The non-moving part, the stator, is made of all the copper coils and is built on the outside which forms the case of the motor. This standard layout is a very common design which is used in a lot of different industries.

- It is Built for High Speed: The main reason this motor is so fast is because the spinning rotor on the inside is very small and light. Because it is so light, it has very low inertia. This means that it does not take a lot of power or time to get it to speed up to its top RPM. It can also stop and change direction almost instantly. This is a very big difference from an outer rotor motor which has a heavy spinning can that takes much longer to get moving.

- It is Great at Cooling: In any motor, the copper coils are the part that gets hot when the motor is working hard. In an inner rotor brushless motor, these hot coils are on the outside wall of the motor’s body. This is a very big advantage because it allows all that heat to escape very easily into the air or into the machine frame. Thai design is a lot better at cooling itself than an outer rotor motor where the hot coils are trapped in the middle and are harder to cool down.

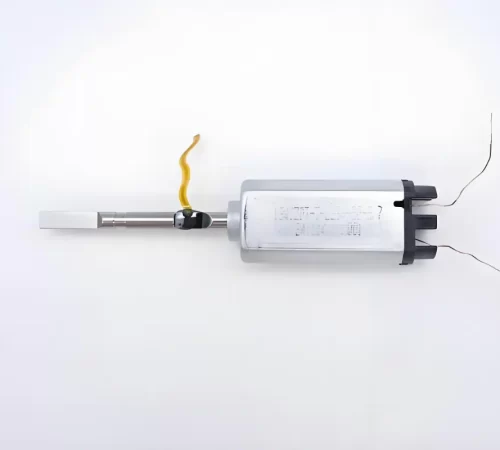

- It has a Long and Thin Shape: This rotor on the inside usually results in a motor that is longer and thinner like a cylinder or a tube. This is different from the “pancake” shape or a lot of outer rotor motors. This long and thin shape is a much better fit for a lot of industrial tools, handheld medical devices and other machines where the motor needs to fit into a long and narrow space. It is a very common and trustable shape for all kinds of applications.

Add Speed to Your Machine!

The inner rotor brushless motor is the industry standard for a good reason. It is the best choice for any job which needs very high speed, fast acceleration and a motor which can keep itself cool while it is working hard. It has a simple and classic design which makes it a workhorse for a lot of different high-speed tools and machines. Contact us and we will help you find a high-speed motor for your application.

Frequently Asked Questions

Is this Motor the Same as a “Normal” Brushless Motor?

Yes, when most people talk about a brushless motor this is the design that they are thinking of. The inner root style is the most common and traditional type of brushless motor. The motor in a high-power handheld drill or an electric car is almost always an inner rotor motor.

Why is this Motor Better at Cooling Than an Outer Rotor Motor?

This motor is better at cooling because the parts that get hot (the copper coils) are on the outside edge of the motor. This lets the heat escape easily. In an outer rotor motor, the hot coils are in the middle, and the spinning can on the outside traps the heat in which makes it much harder to cool down.

What Does Low Inertia Mean for This Motor?

Low inertia means that the spinning part of the motor is very lightweight. Because it is so light, it does not take much power or time to get it moving. This is why the motor can speed up to 60,000 RPM in a fraction of a second and then stop just as fast.

Is This Motor Good for High-Torque Jobs?

No, this motor is a high-speed specialist. If you need a lot of turning force (torque) at a slow speed then an outer rotor brushless motor is a much better choice. The outer rotor has a wide pancake shape which gives it more opportunity to create a lot of torque, but it cannot spin as fast as this inner rotor motor.

Does this Motor Also Need an ESC or a Controller?

Yes, it does. All brushless DC motors including this one needs to have an electronic speed controller (ESC) to run. The ESC is the brain that sends the power to the motor coil in the correct order to make it spin. As your inner rotor motor manufacturer, we can help you find the right controller.