Find the Best Linear Motor for Linear Motion in Your Products

When tasks need movement along a perfectly straight path, the linear motor can offer a great way to get things done. Unlike regular motors which spin to create a motion, a linear motor produces a force directly in a straight line without needing gears or even screws to change the movement. You can find these motors in advanced manufacturing, high-tech sorting systems, and specialized transport lines where exact positioning is necessary. With a linear motor, you get a strong, controlled push or pull for applications that need very clear and direct back-and-forth action.

At YueQing GuangHui Electric Co., Ltd., we understand the increasing demand for systems that move things in a direct and controlled way. We also know that for a lot of modern processes it is a good benefit to have motion directly where it is needed without any additional parts. So, as a linear motor manufacturer, we manufacture linear motors with a focus on providing you with these advanced solutions. We want to be your trusted linear motor provider for components which can allow for exact linear movement.

Benefits of Linear Motor

- Direct Push and Pull: The core benefit of these motors is their ability to produce force directly without the need for turning parts. It can be the driving force for itself when it needs to drive on a straight path.

- Changes in Position: These motors can help to move objects along a line rapidly and stop at the exact points without overshooting. Their design is perfect for swift starts and stops, and almost any instant change in the direction.

- Travel: Since the linear motor has no brushes or gears to have contact with, it has very less friction or vibration. This way, it makes sure to have a smooth movement along the lines.

- Long Life: This simple design with very few moving parts that touch, makes these motors last a very long time. There is less wear out which lowers the need for regular checks or repairs.

- Strong Force: A linear servo motor can give you the same amount of push or pull force along the travel path. While rotating motors sometimes lose power at some point in their cycles, a linear motor can provide strength which stays steady.

Time to Order!

If your systems demand direct, reliable, and highly controlled straight-line movement then a linear motor is an excellent choice. At YueQing GuangHui Electric Co., Ltd., we are your linear motor supplier who deliver high force linear motor solutions which are made for steady and precise operation. Contact us to get motor options which deliver what is required for your applications. We are here to help you achieve consistent and straight movement.

Frequently Asked Questions

How is a Linear Motor Different From a Normal Spinning Motor?

A normal motor like a DC or brushless motor spins in a circle to create rotary motion. A linear motor is different because it has been “unrolled” to be flat. It does not spin at all; it moves back and forth in a straight line which is called linear motion.

What are the Two Main Parts of a Linear Motor System?

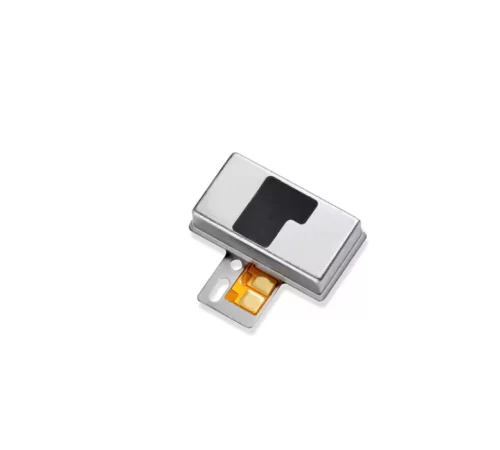

A linear motor system has two main parts that work together. The first part is the flat track which is called the “stator”. The second part is the moving block that rides on the track which is called the “forcer.” The forcer is the part that moves your machine’s load.

Why Would I Use this Motor Instead of a Motor with Gears and a Belt?

You would use a linear motor when you need very high speeds and very exact positioning. A system with belts or gears has extra parts that can stretch, slip, or wear out over time. A linear motor moves directly so there are no extra parts which means there is no backlash and the movement is very precise.

What Kind of Machines are these Motors Used for?

As a linear motor manufacturer, we see these motors used in high-tech machines. They are used in things like CNC machines for cutting fast-moving “pick and place” robots on an assembly line and in 3D printers. Any machine that needs to move something very quickly and stop at an exact spot might use one.

Does this Motor Need a Special “Driver” to Make it Work?

Yes, it does. A linear motor works a lot like a brushless motor and needs an electronic “driver” or “controller” to run. The driver sends the power to the motor to make it move along the track. A linear motor provider can help you match the motor to the correct driver for your project.